Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Technical field

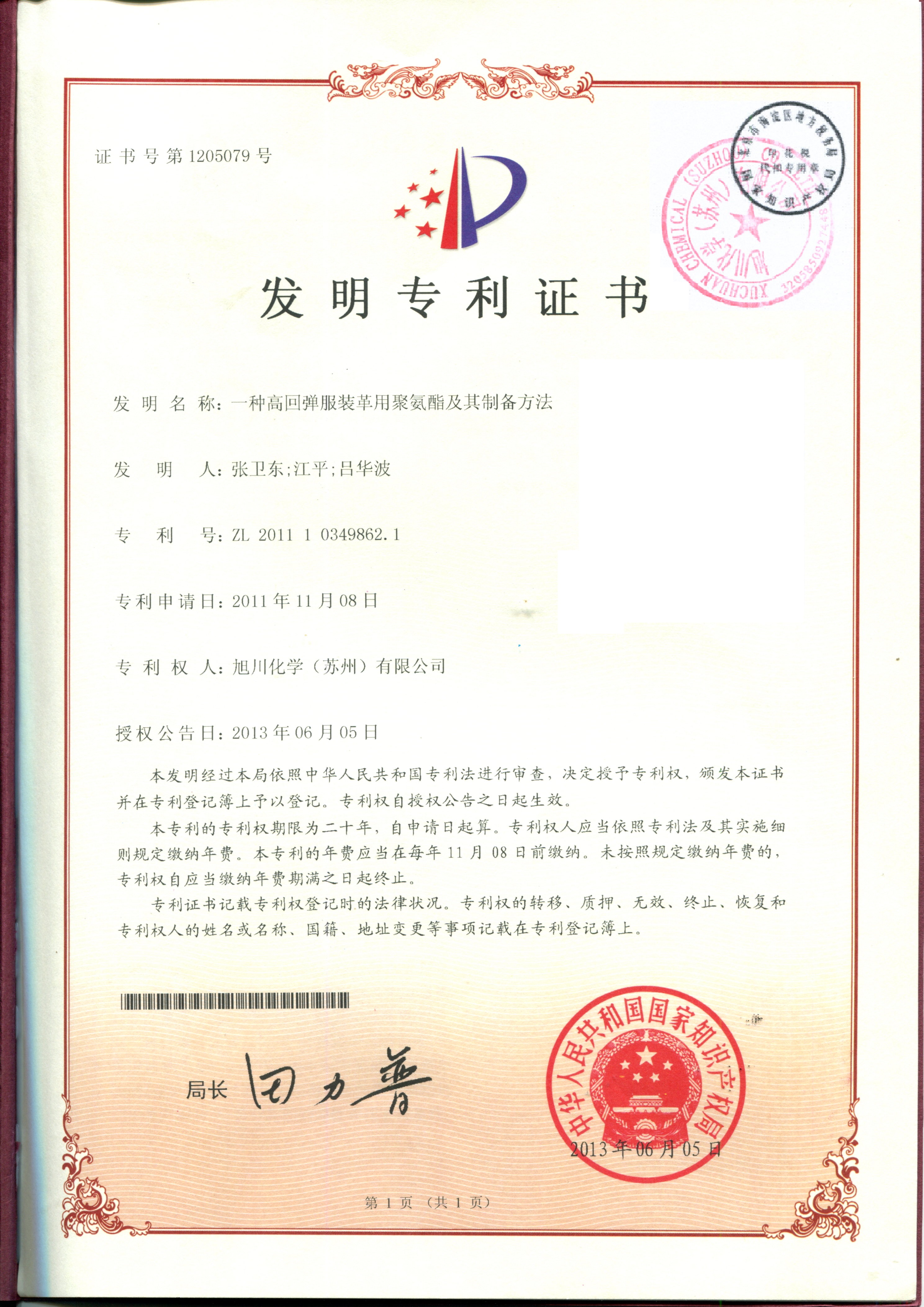

The present invention relates to a polyurethane resin, particularly to a polyurethane for high-resilience clothing leather.

Background

Polyurethane (PU) synthetic leather has the characteristics of soft luster, soft feel and excellent mechanical properties, making it the most ideal alternative to natural leather leather. Polyurethane synthetic leather has been developed for decades and has been widely used in many fields such as clothing, bags, shoe leather, furniture and automobiles. In recent years, synthetic leather technology has been rapidly developed, especially the development speed of synthetic leather for clothing leather is far ahead of other fields.The processing of polyurethane synthetic leather is a conventional wet process, that is, the polyurethane resin containing dimethylformamide (DMF) is coated on the jaw surface of the base cloth, and the polyurethane tree flies are condensed by the method of DMF exchange within the water and resin to form a polyurethane layer with a microporous structure. Usually the sex and feel of leather are determined by the resin it uses, and the change of resin type can obtain synthetic leather products of different species.

The existing polyurethane for clothing leather is usually a mixture of polyester polyols and polyether polyols as polyol components, with ethylene adiyl or butanediol as a chain expander.For example, the Chinese invention patent ZL200810107274.5 disclosed polyurethane for clothing leather, the raw material formulation includes a molecular weight of 2000 polyethylene glycol butanediol adipic acid copolymer glycol glycol 8% ~ 10%, molecular weight of 2000 polyethylene glycol ether 8% ~ 10%, ethylene glycol 0.6 ~ 0.8% and so on.Other patents also improve the composition of polyols constituting a polyurethane body, to achieve the purpose of improving the performance of clothing leather such as labor resistance, wear resistance and other properties. But so far, clothing leather made of these existing polyurethanes is generally lacking in elasticity and pleat recovery.

Contents of the Invention

The technical problem to be solved in the present invention is to overcome the shortcomings of the prior art, to provide a polyurethane for high resilience clothing leather.

The present invention also provides a polyurethane preparation method for high resilience clothing leather.

To solve the above technical problems, one of the technical solutions taken by the present invention is:

A kind of polyurethane for high-resilience clothing leather, in terms of weight percentage, the raw material formulation of the polyurethane is: the average amount of polyacetate 2000 ~ 6000 polyadinyl glycol glycol 16% ~ 24%, 1,3- propylene glycol 0.8% ~ 1.5%, 4, 4- diphenylmethane diisocyanate 5% ~ 9% and the residual amount of dimethylformamide.

According to a preferred aspect of the present invention, the raw material formulation of the polyurethane is: several average molecular weight 3000 ~ 6000 polyethylene adipic acid glycol glycol 18% ~ 22%, 1,3- propanediol 0.8% ~ 1.5%, 4,4- diphenylmethane diisocyanate 5% ~ 7% and the residual amount is dimethylformamide.

Preferably, the number of polyadipate glycol glycols are molecular weight 4000 ~ 6000.

Another technical solution taken by the present invention is: a method for preparing polyurethane for high-resilience clothing leather, which is to add the formulation amount of polyethylene adipic acid glycol glycol and 1,3- propanediol to the reactor, heated to 100 ° C ~ 110 ° C, dehydrated to an anhydrous state, cooled to 40 ° C ~ 50 ° C, added to the formula amount of 4,4- diphenylmethane diisocyanate, and then heated to 70 ° C ~ 90 ° C for bulk polymerization reaction, the viscosity is monitored during the reaction, until the viscosity reaches 1.2MCps/25 °C, add the formula amount of dimethylformamide, stir well, filter packaging to obtain the high resilience clothing leather with poly.

Due to the adoption of the above technical solution, the present invention has the following advantages compared to the prior art:

Different from the conventional use of ethylene glycol or butanediol as a chain expander in the formulation, the polyurethane of the present invention employs 1, 3- propylene glycol as a chain expander, and combines a specific Polyester Polyol and isocyanate components and the dosage of each component is reasonably proportioned. Garment leather processed using polyurethane of the present invention, having high resilience and excellent pleat recovery. Further, the polyurethane formulation of the present invention is simple, can be prepared by bulk polymerization method, low production cost.

The preparation method of polyurethane of the present invention is simple to operate, does not require highly complex separation and purification, it can be obtained polyurethane of high purity, garment leather processed using this polyurethane, with high resilience and excellent fold recovery.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.