Polyurethane resin price casting PU for shoe Insole

Get Latest Price| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1000 Kilogram |

| Transportation: | Ocean |

| Port: | Shanghai |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1000 Kilogram |

| Transportation: | Ocean |

| Port: | Shanghai |

Model No.: A-2001/B-8580

Brand: Xuchuan Chemical

Place Of Origin: China

Types Of: Synthetic Resin And Plastics

Characteristic: Good handle, low density and good dimension stability, high elasticity

Appearance: liquid

Code: A-2001/B-8580

Brand: Xuchuan

Application: shoes insole

Polyurethane resin price casting PU for shoe Insole

Polyol Isocyanate For Mid-Sole

Name of products:A-2001/B-8580

Characteristic: Good handle, low density and good dimension stability, high elasticity

Application: Insole and low density mid-sole

| Application | shoes insole |

| A/B Materials Temperatures (℃) | 40~45/38~42 |

| A+C/B Mix ratio (By weight) | 100/74~76 |

| Cream Time (s) | 7~9 |

| End of Rise Time (s) | 50~60 |

| Free Rise Foam Density(g/cm3) | 0.13~0.16 |

| Mold Temperature (℃) | 45~55 |

| Molded Density (g/cm3) | 0.30~0.40 |

| Hardness (Shore C ) | 35~45 |

| Tensile strength(MPa) | Tensile strength(MPa) |

| Characteristic: Good handle, low density and good dimension stability, high elasticity | |||||||

| Application: Insole and low density mid-sole | |||||||

| Typical properties of PU matrix | |||||||

| Name of products | Appearance | Viscosity (mPa·s/40℃) | Density (g·cm-3/40℃) | Package(kg) | / | ||

| A-2001 | Liquid | 1000~1400 | 1.01~1.02 | 18 | |||

| B-8580 | Yellowish transparent liquid or waxy | 600~1000 | 1.08~1.2 | 20 | |||

| Materials preheat | |||||||

| A-2001: preheated at 50~60℃ for 8~10 hours. | |||||||

| B-8580: preheated at 50~60℃ for 8~12 hours. | |||||||

| Typical processing parameters & Reaction parameter | |||||||

| Items | A/B Materials Temperatures | A+C/B Mix ratio | Cream Time (s) | End of Rise Time (s) | Free Rise Foam Density(g/cm3) | Mold Temperature | Demold Time(min) |

| Parameter | 40~45/38~42 | 100/74~76 | 7~9 | 50~60 | 0.13~0.16 | 45~55 | 4~5 |

| The adding content of C-2 should be 300g±20g/18kg. | |||||||

| The adding content of water should be 0~90g/18kg according to the reality. | |||||||

| Physical properties | |||||||

| Items | Molded Density (g/cm3) | Hardness | Tensile strength(MPa) | Elongation (%) | Tear Strength | / | |

| Physical properties | 0.30~0.40 | 35~45 | 4.0~6.0 | 300~380 | 18~26 | ||

| Demold time may be prolonged with the increase of sole thickness | |||||||

| These physical data are acquired by testing a sample of 6mm thick. | |||||||

| | |||||||

Data listed above are just for reference. The detail data are subjected to practical production. If other requests for physical properties, please contact us.

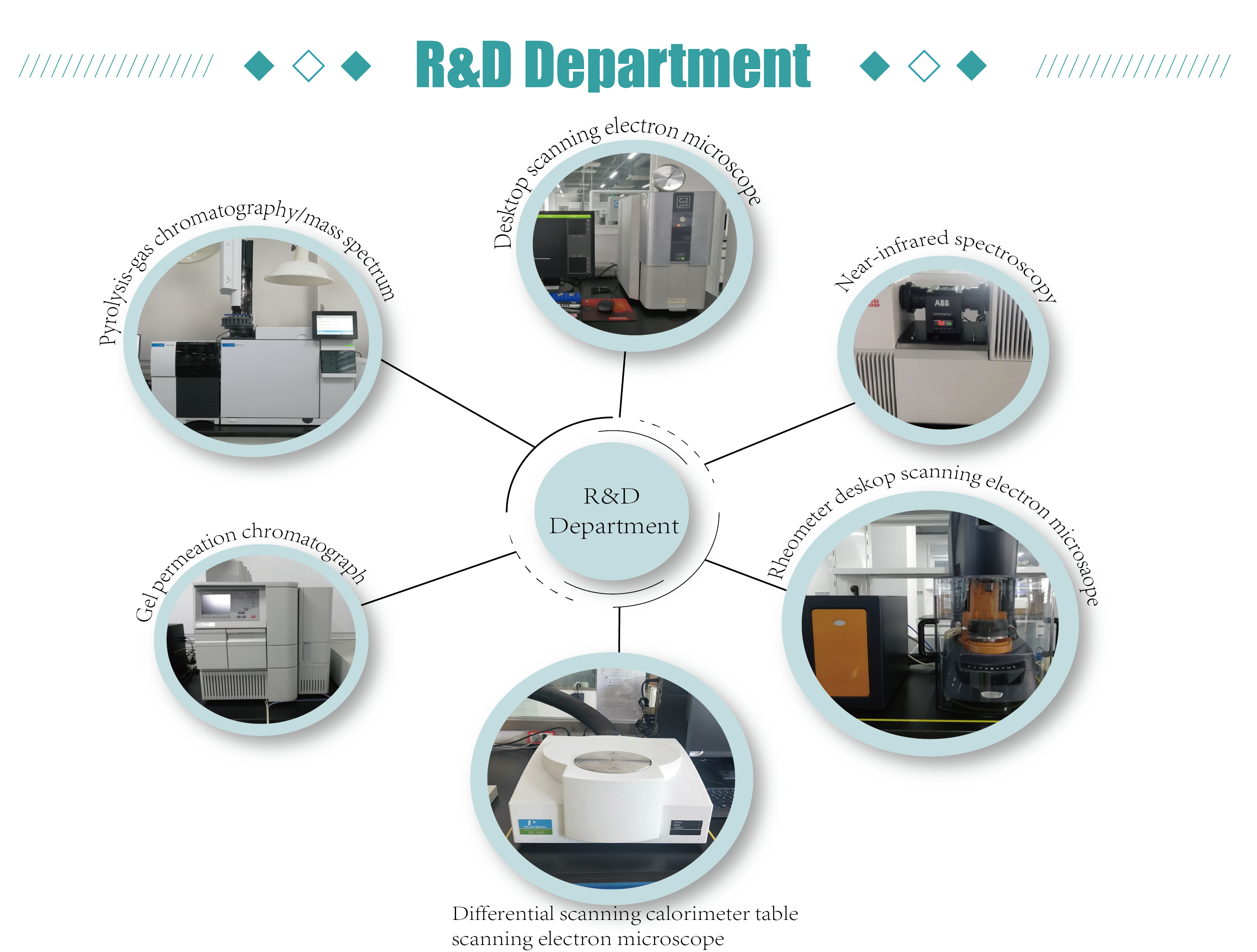

Xuchuan chemical established in 2007, company registered capital is RMB 500 million. The main products are all ranges polyester polyol, polyurethane resin for shoes, water-based and solvent-free polyurethane resins for artificial leather, polyurethane bonding adhesives and polyurethane hot melt adhesives.

Now Xuchuan has 4 modern production bases, production capacity reached 630,000 tons per year, products exported to 32 countries and regions in the world.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.