PUR for textile use pur hot melt glue

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Min. Order: | 3 Ton |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Min. Order: | 3 Ton |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Model No.: XCUR-5130

Brand: Xuchuan Chemical

Place Of Origin: China

Types Of: Synthetic Resin And Plastics

Brand Name: Xuchuan

Model Number: XCUR-5130

Appearence: liquid

Keywords: PUR for textile

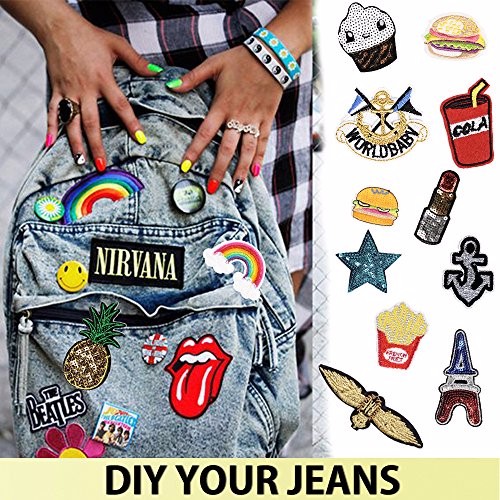

Application: widely used in garment fabric, medical supplies, industry fabric.

Properties: high strength and tenacity fitting effect after cured.

Characteristics 1: long pot-life, low operated temperature

Characteristics 2: fast curing speed with good initial adhesion

Moisture-curable polyurethane hot melt adhesive for textile

Reactive Polyurethane Glue Description:

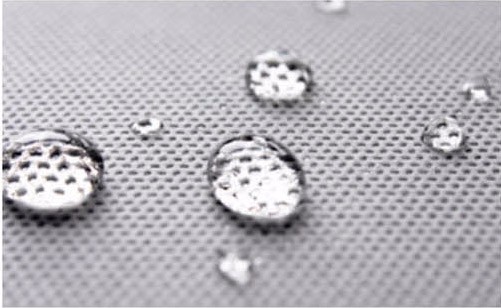

XCUR-M5130 is a one component moisture-curable polyurethane hot melt adhesive used for textile fabric composite and fitting composite of water-proof fabric and TPU films.

Specification:

| Properties | Code |

| Solid content (%) | 100 |

| Viscosity(Ps/120℃) | 13000±3000 |

| Appearance | Paste |

| 100% M(Kgf/cm2) | 12~16 |

| T.S(Kgf/cm2) | 100~120 |

| EL(%) | 400~600 |

Moisture Curing PU Adhesive Properties and Applications:

Characteristics: long pot-life, low operated temperature and fast curing speed with good initial adhesion. it can achieve soft feeling with high strength and tenacity fitting effect after cured.

Usage: widely used in garment fabric, medical supplies, industry fabric.

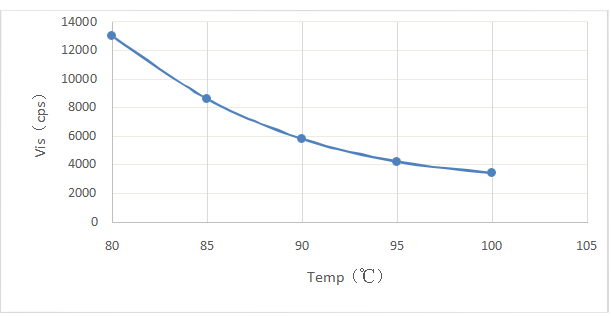

Viscosity curve

Processing suggestion

1.Process temperature: 80~100℃.

2.Process humidity: >50%, the curing speed can be improved if the ambient humidity increased.

3.storage: stored in sealed Package. in case of moisture, there would be a solidified film on the surface and the viscosity would dramatically increase.

4.When you used PU Reactive HMA , don’t subpack it again and use it to finish.

5.Shelf-life: 6 months.

Cleaning

1.Waste cloth is suggested to wipe out the residual PUR Hot Melt Adhesive on nozzle or barrel.

2.Mix the unreacted PUR hot met adhesive with special cleaning agent for 5 to 10 min.

Other Reminds

1.Personal protective equipment(PPE) is essential in case of scald.

2.Please use it in a well ventilate condition in case of allergic effects for the long-term contact with a small amount of isocyanates in the product.

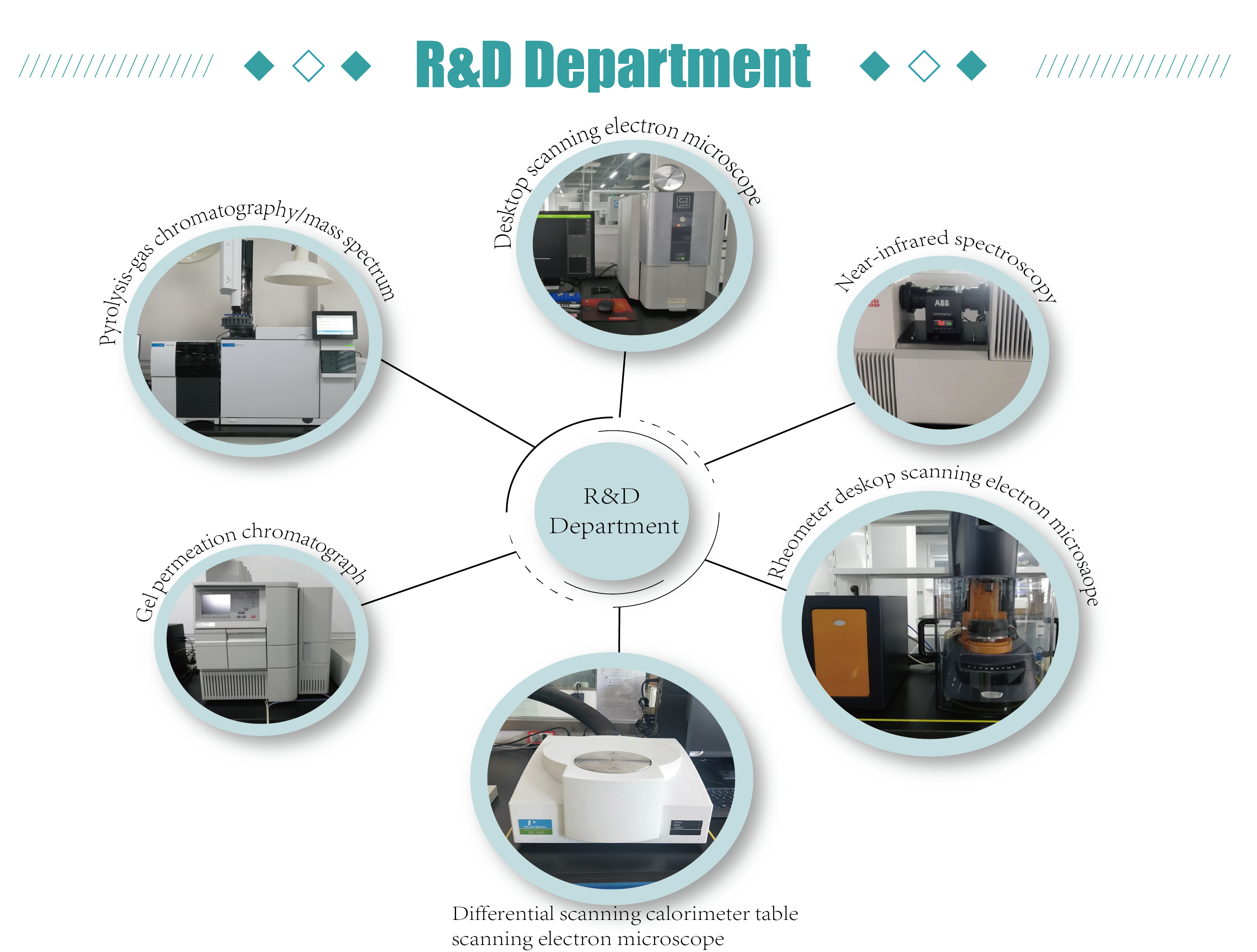

Xuchuan chemical established in 2007, company registered capital is RMB 500 million. The main products are all ranges polyester polyol, polyurethane resin for shoes, water-based and solvent-free polyurethane resins for artificial leather, polyurethane bonding adhesives and polyurethane hot melt adhesives.

Now Xuchuan has 4 modern production bases, production capacity reached 630,000 tons per year, products exported to 32 countries and regions in the world.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.